Avalon Vision Solutions provides a wide range of injection mold protection solutions tailored to the needs of the injection molding and die cast industries, aimed at preventing CARs. Our flagship product, MoldWatcher, automatically inspects for inserts and part quality during the molding process, as well as cavity, core, and slides after the part is ejected. In addition, our new ThermalWatch technology detects temperature changes that are beyond the capacity of human vision. With our cutting-edge solutions, we are dedicated to meeting the unique demands of your industry.

What are CARs?

Corrective Action Requests (CARs) are formal requests or documentation that identify a problem or nonconformity within a process, product, or service, and propose a course of action to correct or prevent the issue from recurring. CARs are typically initiated when a deviation from established standards or procedures is identified, or when a customer complaint is received. The primary purpose of a CAR is to identify the root cause of the problem, take corrective actions, and prevent similar issues from occurring in the future. CARs are a commonly used tool in quality management systems, and are often a critical component of continuous improvement programs in organizations across various industries.

Real life solution:

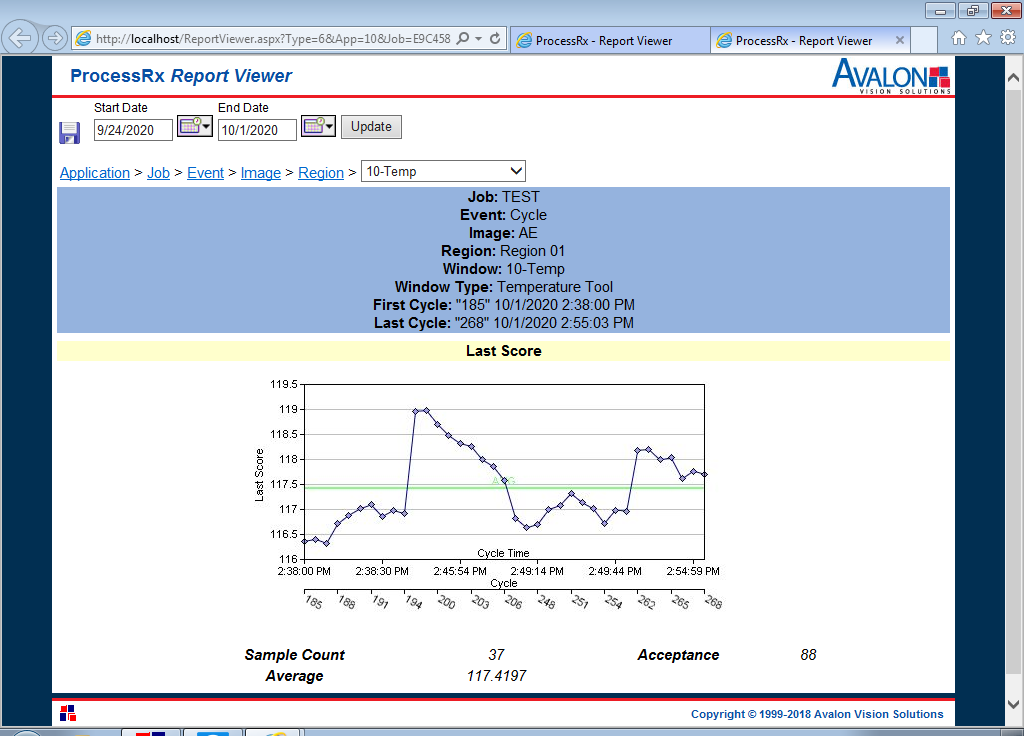

A medium sized Tier I supplier to the one of the big three US automotive companies was able to stop Charge Backs and Corrective Action Requests by implementing ProcessRX™ into their Quality Station inspection stations performing Sequencing. Inspection stations with ProcessRX™ kept track of each final assembly by serial number and were able to print PDF reports showing the product had left their plant fully assembled with no further damage. The actual PDF image reports of the final product were reviewed by the customer and all disputes were immediately settled. This was an incredible cost savings.