THE ONLY COMPLETE INFRARED SYSTEM

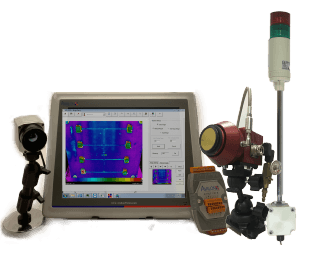

ThermalWatch is a complete Infrared Camera machine vision system with all components needed to interface and setup on processes or equipment. It can be installed and running within a few hours. The system can be used to measure and verify temperatures in many manufacturing processes.

Temperature change detection during production runs allows resolution of issues that otherwise are unmeasurable by the human eye. Engineers can detect process variations before it affects final product quality and adjust production equipment accordingly.

HOW THERMALWATCH WORKS

THE MOLD OPENS

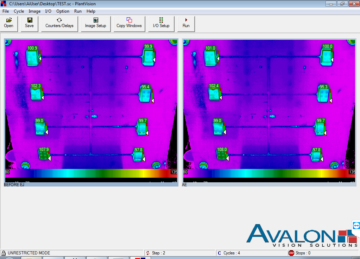

Before Ejector Image is Taken of Moving Side

Surface Temperature of molded parts is confirmed to be in the proper temperature tolerance. In addition, presence of the part is verified so that it is known that all parts left are in the fixed side.

Ejection is Enabled

If all parts are present and within designated temperature range, then the Ejection Cycle is enabled. Otherwise, the press is stopped, alarm activated, and the failed inspection is displayed.

Ejection is Complete

After Ejection Image is Taken on Empty Side

The relative temperature of the mold surface and the proper ejection of the

parts can be verified. If all is within tolerance, then the mold is permitted

to close. Otherwise, the same failure routine as #2.

THERMALWATCH PROVIDES

WHAT IS INCLUDED?

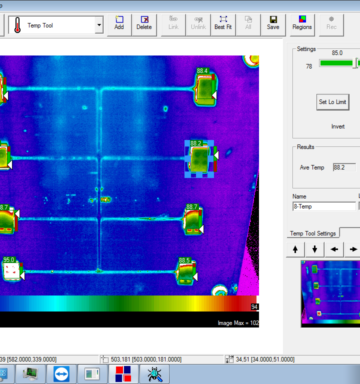

Our powerful ThermalWatch software powers the entire system. It was created specifically to be configurable via touchscreen menus to interface to all equipment controls in minutes. Image processing setup is configured via simple temperature measurement tools.

The thermal camera provides system accuracy at ambient temperature +/- 2 Degrees C or +/- 3.6 Degrees F or +/- 2% (after calibration at process temperature)

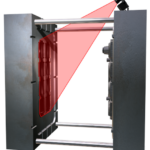

For Harsh Environment applications, we have designed a custom enclosure to ensure safety of camera during the inspection process.

ThermalWatch Vision computer includes an easy to use 12” or 15” touchscreen that runs on Windows OS.

E-NET I/O module has 8 digital inputs and 8 relay-based outputs to be able to interface to any equipment controls. Completely configurable via the Cycle Setup for any continuous or state driven process.

The alarm tower alerts via sonalert and red/green light when the process equipment stops due to a failed image.

There are two sizes of our power supple. 50 watt, 24Vdc or 120 watt, 24Vdc.

The camera and light can be mounted with a magnetic or bolt-on flex mount.

The controller can be mounted on a swing arm, magnetic mount, or on a mobile stand.

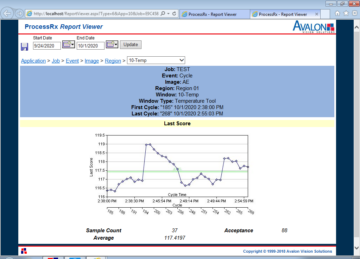

PROCESS RX

Avalon’s optional ProcessRx™ for ThermalWatch is an important addition to the powerful inspection system. The process documentation module with image database, event logging and statistical reports is the most advanced and easy to use process documentation system available. The Internet Explorer web browser permits remote access using the LAN, however most problems are exposed when the user can see an actual image of the inspection. ProcessRx™ can be configured to save all the Failed images, all of the Passed images, or both.

This powerful configuration technique allows the user to define exactly what data they need to capture. Data is stored in an SQL database and can be easily exported to other file types and databases, including other process monitoring applications.